Menu

Measuring cases, advice & data analysis

Energy management starts with insights. Insight into the actual consumption of machines and production lines. Especially after years of use and halfway through the maintenance cycle, when things no longer go by the book. It saves costs, motivates staff and reduces CO2 emissions: demonstrable to government and shareholders both in advance and after the fact. Now that’s what we call a win!

A measurement plan reveals opportunities

What is already being measured? How is that data being used? Where is the peak load and to what extent has it been accounted for? A good measurement plan is not a matter of ‘simply sending a quotation’. We talk to your financial controller and plant manager to draft a targeted plan that can be executed in stages, if so desired, with a predetermined savings amount.

- We offer a measurement plan of €975.

- The average savings amounts to 30% of your energy bill.

- Our solution is suitable for energy consumption starting at €250,000/year.

From data to dashboard

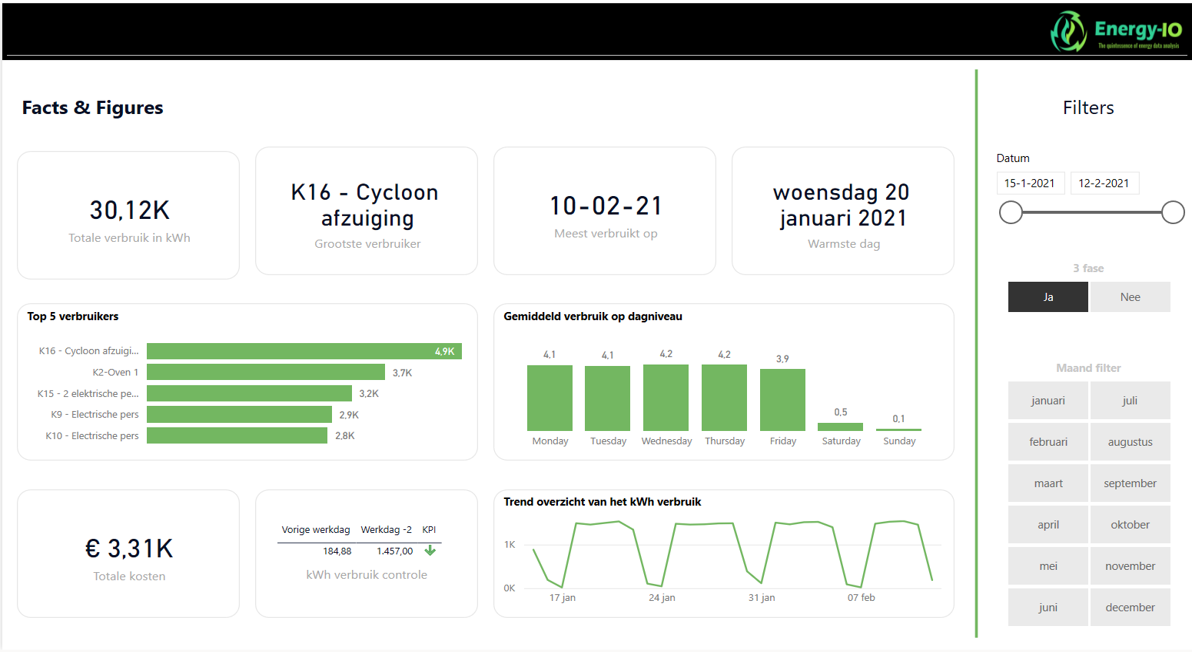

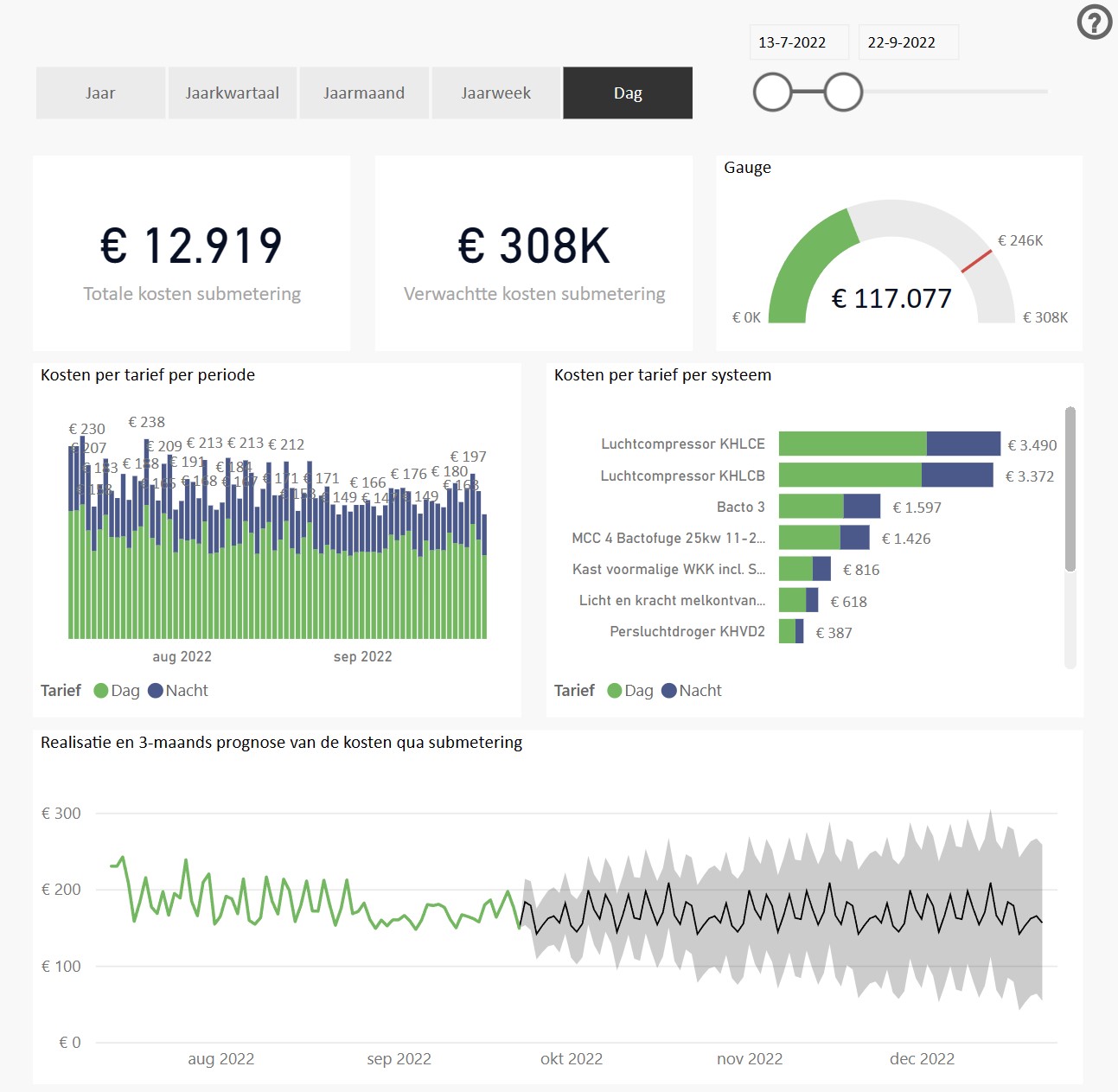

Energy consumption measurements are meaningless unless they are linked to business parameters such as production level, climate, product type and other company-specific parameters.

Our dashboards visualise any deviations immediately thanks to our Artificial Intelligence-based algorithms, allowing you to make corrections quickly and efficiently. The dashboard is administered by your own people: production officers, technical department personnel or your energy officer. Of course, we are here to help as well.

Measuring case as a smart meter

Ten years ago, we introduced the smart (sub)meter for the manufacturing industry, to measure energy consumption per machine or production line. The equipment is now delivered in plug & play measuring cases that are read and maintained remotely.

This reduces the number of people at your location without missing out on state-of-the-art smart metering. It dramatically reduces the costs per measuring point (factor 4 to 5) and installation is much faster as well. The measuring cases can be installed by your own mechanics or preferred contractor. Energy-IO’s team will support both installation and commissioning.

Advice and business cases

Stakeholders require good substantiation of investments and retrospective accountability. Our advisory service supports or facilitates your calculation of business cases. Not with estimates, but with real data. We offer this service on an interim or consultancy basis.

saved on energy bills

<

0

%

Practice

The importance of good measurement is proven every day. One client decided to revise an injection moulding machine to save costs. The update dramatically improved the process, but the machine was now consuming 5x more energy because of an incorrect connection. This case demonstrates how energy monitoring is important in realising savings as well as to retain optimal performance afterwards.

Isn't it crazy how one can spend three million on energy

without being able to explain where that energy went?

Into the process or down the drain...

Make it lean and mean

Call or email now to schedule an introduction, so we can estimate whether a measurement plan is the right starting point for you. We help the manufacturing industry save an average of 30%. If your commercial consumption amounts to at least €250,000, our service pays for itself within a year.

- Hengelo

- Haaksbergerstraat 67

- 7554 PA Hengelo

-

- info@energy-io.nl

- +31 (0)85 078 27 66

- Menu

Menu